Whether you realize it or not, industrial minerals are a fundamental part to our everyday lives. The mining industry supplies the necessary minerals to make modern life work. Yet most people remain unaware of just how ubiquitous the use of mineral resources is in their own lives, down to the simplest pleasures. Probably the most common misconception about minerals is that we can do without them. To understand the changing world of minerals, look to the ones that power the devices around you. Every component involved in today’s technology, including computers, smartphones, solar panels, and batteries originates from minerals. Advances in electronics are driving the recent explosion in mineral usage. More than 100 billion integrated circuits exist worldwide;1 a massive accomplishment that wouldn’t have happened without the use of many commonly used minerals.

Industrial minerals are geological materials which are mined for their commercial value, which are not sources of metals but are used in the industries based on their physical and/or chemical properties. They are used in their natural state or after beneficiation either as raw materials or as additives in a wide range of applications. Industrial minerals are extremely versatile; most have at least two, sometimes many more, applications and span multiple markets. Industrial minerals are used, either in processed or natural state, to make building materials, paint, ceramics, glass, plastics, paper, electronics, detergents, medications and medical devices, and many more industrial and domestic products.

Worldwide annual demand for lithium was about 350,000 tons (317,500 metric tons) in 2020.1 Despite expectations that lithium demand will rise from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to some three million to four million metric tons in 2030, McKinsey & Company believe that the lithium industry will be able to provide enough product to supply the rapidly growing lithium-ion battery industry.2

The following are four of the highest profile uses of minerals illustrate just how deeply we rely on them:

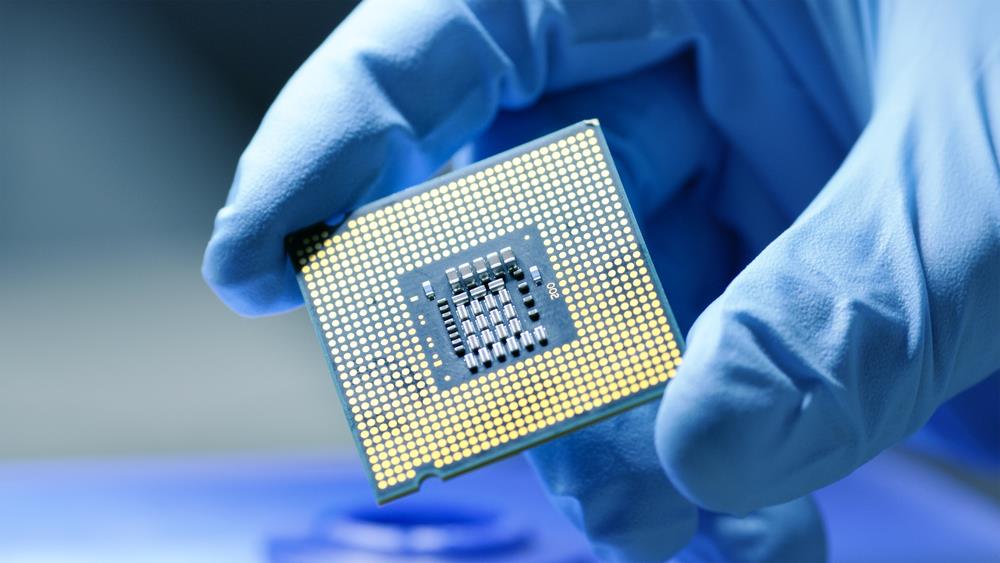

Electronics: Silica is so common in electronics manufacturing that Silicon Valley, the region that brought us Intel and Apple, was named after it. Computers can communicate with one another because of lightweight semiconductors like silica (Figure 1). In fact, electronic devices rely on combinations of many mineral elements like silica and wollastonite.

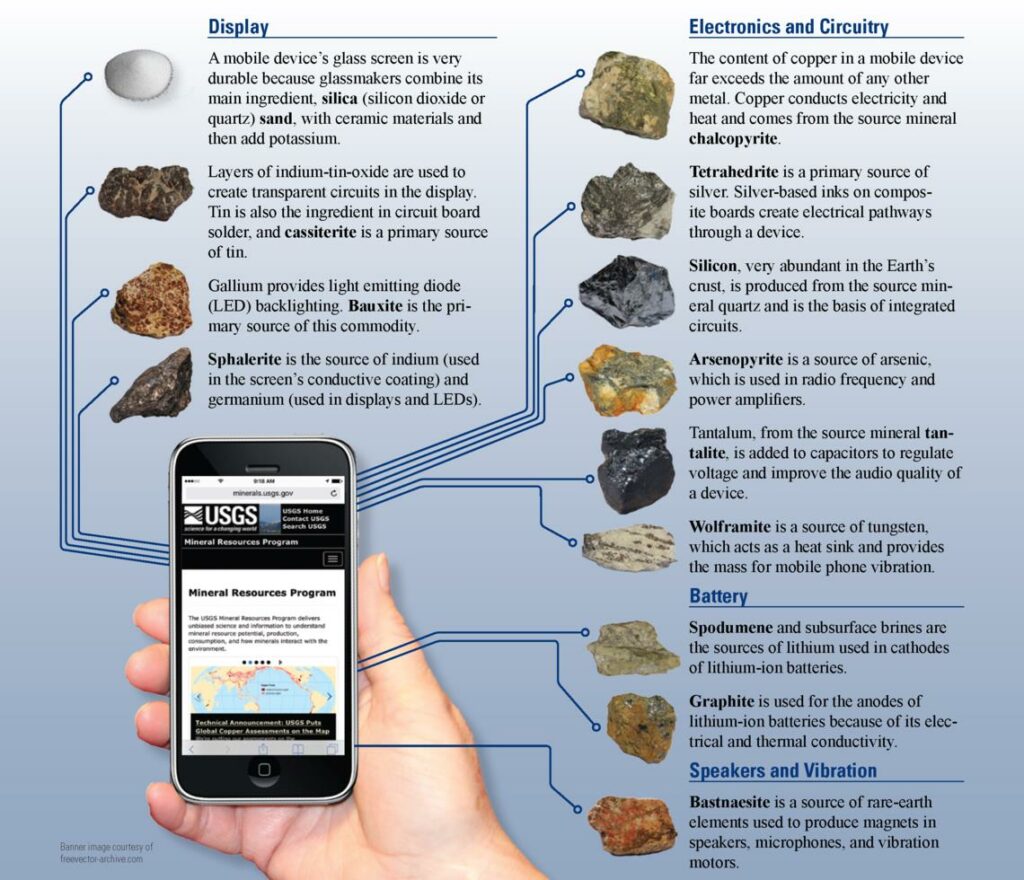

Smartphones: A single smartphone requires the unique capabilities of more than 30 different chemical elements (Figure 2). The glass screen gets its durability from silica sand, and other materials.

Batteries: Pretty much everything we have these days that needs a lightweight battery ― lights, laptop computers, smartphones, or electric cars ― uses lithium (Figure 3). Lithium batteries range from a 10-watt mobile phone battery to a 650-pound electric car battery containing 9 pounds of lithium. Rechargeable batteries will continue to play a significant role in the green energy movement as a means of curbing global warming.

Cars: A decade ago few electric cars were on the road. Now most auto manufacturers are planning to build electric vehicles if they haven’t done so already. As society weans itself of fossil fuels, more environmental models are using a wider variety and a larger amount of certain minerals. Talc is mixed with other minerals to create automotive plastics (Figure 4). Talc creates a balance of rigidity and impact strength in these plastics to allow the parts to be thinner and lighter, lowering the overall vehicle weight thereby improving energy efficiency. Talc also creates enhanced permeability in rubber, which improving the resistance of tires and fuel efficiency.

We use things made from rocks and minerals every day. It is estimated that every American consumes 24 tons of industrial minerals each year. Every segment of society uses minerals and mineral resources. The roads we ride or drive on and the buildings we live, learn, and work in all contain minerals. Below is a list of commonly used industrial minerals that are used to make products we use in our daily life.

Ball clay is commonly used in the fabrication of ceramic articles including sanitaryware, tableware, ceramic whiteware, wall and floor tiles, and glazes. Ceramic tiles are durable, rigid, and environmentally friendly. The US Green Building Council mandated the use of eco-friendly materials, and ceramic tiles are on the good list.2 Sanitaryware is the second largest industry, accounting for 18% of ball clay in the United States. Sanitary ware is necessary for personal and commercial bathrooms and kitchens (toilets, sinks, etc.).3 Some non-ceramic applications include the construction industry; horticulture, agriculture, and amenity industries; use as fillers and extenders in polymers, adhesives, plastics, sealants, fertilizers, and insecticides.

Barite is primarily used as a weighting agent in oil and gas exploration. It controls pressures and prevents explosions. This is the cause for 90% of barite sales in the United States. Because of this, trends of barite consumption mirror trends of drilling rig counts. Barite is also used in the production of a cement jacket around underwater petroleum pipelines to reduce leakage and protect the pipes. Barite is used as a filler and weighting agent in paints, plastics, and rubbers. It is used in the production of automobile brake and clutch pads, and automobile paint primer for metal protection and glass. In the medical field, barite can be used to block x rays and gamma ray emissions during medical studies. Ultrapure barite can also act as a medical contrast in gastrointestinal studies. Barite is also used in the cosmetics industry primarily to produce lipsticks and lip-glosses.

Bentonite is used in agriculture, animal feed, construction and civil engineering, detergents, household products, industrial coatings, cat litter, wine and juice clarification, health benefits (stomach pain, healthy gut, skin health), water treatments, heavy metal removal. Metal casting is among the most important current uses of bentonite. Engine blocks, brake drums, transmission housings, manhole covers, street drains, cast-iron pans, and more are produced from foundry molds containing bentonite. Bentonite is used as a binder for the formation of iron ore pellets, which are then used in iron making. In the drilling mud industry, bentonite is used to lubricate and cool tools to prevent blowouts and reduce drilling fluid invasion. Bentonite is ideal for cat litter and as a desiccant due to its water absorption properties, and a great anti-caking agent for animal feed. The unique ability of bentonite to absorb water, swell many times its dry volume, and yield extremely low water permeability makes it an excellent sealant for environmental applications. Bentonite is widely used in combination with cationic polymers to flocculate cellulose fibers during paper making.

Calcium carbonate is the most widely used mineral in the paper, plastics, in the paints and coatings industries both as a filler – and due to its special white color – and as a coating pigment. In the paper industry it is valued worldwide for its high brightness and light scattering characteristics and is used as an inexpensive filler to make bright opaque paper. Calcium carbonate is used widely as an effective dietary calcium supplement, antacid, phosphate binder, or base material for medicinal tablets. Calcium carbonate is critical to the construction industry, both as a building material (e.g. marble), and as an ingredient of cement. It contributes to the making of mortar used in bonding bricks. Calcium carbonate is used in the production of plastics products and has many benefits including: improved quality with heat resistance and stiffness, the ability to allow plastics to heat up and cool down quicker during processing.

Diatomite – Due to their unique honeycomb structure, diatomite is used as a filtering media including swimming pools, beverages, motor oil processing, and pharmaceutical manufacturing. In paints, diatomite alters gloss and sheen, extends primary pigments, adds bulk and strength, controls permeability and enhances coating adhesion. Diatomite is highly absorbent and is useful in the clean-up of spills in the automotive, industrial, janitorial, and waste remediation industries. When diatomite is incorporated into soil, it serves to reduce compaction, and increase water and air permeation. When insects contact diatomaceous earth, it absorbs their protective wax coating, and their shells are damaged by the glassy diatoms. This combination causes them to die by dehydration. Other examples of the universe of products and uses which benefit from diatomite include dental fillings, seed coatings, roofing compounds, adhesives, sealants, matches, oil drilling compounds, specialty concretes, and paper.

Feldspar – The industries that use feldspar are for construction, building, ceramics, glass making, fillers and extenders, enamel frits and glazes. In glass making, feldspar reduces the melting temperature so that less energy is used. This also decreases the amount of soda ash used in glass production. The alumina content of feldspar improves the end products hardness, durability, and resistance to chemical corrosion. Feldspar can act as a flux (a material that lowers the melting temperature of another material) in the ceramic industry. Feldspar specifically melts at an early stage to form a glassy matrix that bonds other components together.

Kaolin is used in a variety of different industries including building and construction, ceramics, adhesives, sealants, flame retardants, crop production, rubbers, plastics, coatings, inks, health (digestive), cosmetics, print, and packaging. Kaolin has always been used in the print and paper industry, contributing to the production of magazines, catalogs, brochures, flyers, boxes, labels, etc. Kaolin helps protect the epithelial lining in human digestive tracts, giving the body the space from the food and internal waste it needs to heal. Kaolin based fertilizers are EPA approved to protect agricultural crops, act as an insecticide, and reduce environmental stresses caused by the sun and the heat. Most common toothpaste brands use synthetic silica as abrasive agents, which make up 15-20% of the composition. Their role is to whiten, polish, and smooth enamel. Kaolin is a natural alternative to synthetic silica, with the same ability to clean without damaging enamel.4 Calcined kaolin clay combined with talc can provide a safe barrier from contaminants in medications. The rubber pharmaceutical stoppers mitigate the risk of contamination, provide a longer shelf life, reassure patients their medication is safe, and make patients’ lives easier.5

Perlite Some industries that use perlite are for insulation, oil well treatments, fireproofing, acoustic, horticulture, lightweight aggregate construction, air filtration. Perlite is used as an eco-friendly alternative to polymer based micro beads in body and face scrubs. Perlite is also used to help filter out impurities from wine and fruit juices. Because of the pH, inert, and fireproof properties of perlite, it is commonly used as an insulator in buildings. More specifically, in hollow-masonry unit walls, between exterior masonry walls and interior furring, for under floor insulation and leveling of old floors, in ceiling tiles, and as fireproofing around chimneys and doors. Perlite is an all-natural safe mineral to insulate buildings. Perlite is used immensely in greenhouses to naturally improve growth of seedlings and plants. Since perlite is not a “synthetic” material or a chemical fertilizer, it contains no harmful compounds, and it is a safe alternative to these fertilizers that keep the plants organic. Some benefits of gardening with perlite include its neutral pH, no chemicals, or nutrients, it is highly porous, improves drainage to assist gardeners with water retention.6

Quartz (or Silica) is used by the semi-conductor industry. High purity quartz is used as a base material for the manufacturing of crucibles in the Czochralski (CZ) process, a method of crystal growth to obtain single crystals used in semiconductors.7 Industrial silica is used in a vast array of industries, the main ones being the glass, foundries, construction, ceramics, and the chemical industry. Silica in its finest form is also used as functional filler for paints, plastics, rubber, and silica sand is used in water filtration and agriculture. Other examples of everyday uses include the construction and maintenance of an extensive range of sports and leisure facilities. Crystalline silica is also irreplaceable in a series of high-tech applications, for example in optical data transmission fibers and precision casting. It is also used in the metallurgical industry as the raw material for silicon metal and ferrosilicon production.

Salt is a cost-effective material for maintaining mobility on roads and highways during ice storms and snowstorms. In water conditioners, salt enables the ion exchange necessary for removal of hard minerals from water. In addition to be used for deicing winter roads, water softening, and food seasoning and preservation, salt has over 14,000 uses. Salt is used in the chemical production and manufacture of PVC, plastics, and paper pulp; manufacture of soaps and glycerin; production of animal feed; and as a feedstock for chemical industry.

Soda Ash – The prime use of soda ash is in glass manufacturing including containers, fiberglass, flat glass, commercial buildings, and automotive industries. Soda ash is used to make the most common type of glass, soda-lime silica glass. Soda-lime silica glass is used for bottles, drinking glasses, and windows. It’s light transmission properties and low melting temperatures make it perfect for window glass. Soda ash can be used in the food industry to sweeten soft drinks and relieve physical discomfort (part of sodium bicarbonate). Some other industries that use soda ash are household detergents and paper products, building materials, automobiles, home improvements (internet cables, lightbulbs, etc), cleaning supplies, power generation (flue gas desulfurization), beverages, industrial (lead recycling, chrome manufacturing and planting, hospital garment cleaning, beer and wine equipment cleaning), energy and mining, and water treatment.

Talc is commonly used in everyday life in the automobile, paints, paper, ceramic, agriculture, and other industries. Talc is mixed with other minerals to create automotive plastics. Talc creates a balance of rigidity and impact strength in these plastics to allow the parts to be thinner and lighter, lowering the overall vehicle weight. Talc also creates enhanced permeability in rubber, which improving the resistance of tires and fuel efficiency. Talc can be used as a natural solution to replace the less environmentally friendly titanium dioxide (TiO2). Talc in the pulp and paper industry provides a good solution to avoid harmful mill deposits. This allows mills to work in closed water circuits and use more prime resources. Talc improves the vitrification process in the ceramic industry, allowing producers to reduce firing temperatures and shorten firing cycles. Talc can be used as an alternative to chemicals in the agriculture industry to protect fruit from sun rays and various diseases.

Uintaite is commonly used in the oil and gas industry for drilling fluids, in cementing, asphalt, inks, and paints. The high strength and durability, superior deformation performance, reduced pavement thickness, reduced temperature susceptibility, and increased resistance to water stripping makes uintaite good for asphalt production. Uintaite is used as ink rub resistance in magazines, books, etc., while also an agent for carbon black dispersion. Carbon black is one of the most popular plastic additives, and uintaite is used to reverse the negative effects of this cheap source of black pigment. Uintaite protects paints from various elements, increases UV light stability, and is primarily used for painting roofs.

Wollastonite – The main industries that consume wollastonite are plastics, paints, ceramics, friction products, construction materials, adhesives, and sealants producers. Wollastonite is a cost-effective replacement in the plastics industry for synthetically produced fiber glass. Adding wollastonite to car parts can help improve their strength and impact resistance, contributing to the automotive industry. Because of wollastonite’s high melting point, it can enhance insulating properties and fire resistance in electrical and electronic equipment. It is used in computers, houses, and electrical connectors. In paints and coatings, wollastonite contributes to the flexibility, anti-cracking, gloss control properties, and anticorrosion properties. Wollastonite enables manufacturers to speed up ceramic firing, reducing crazing, cracking and glaze defects. The decreased firing time reduces energy costs and therefore CO2 emissions.

https://www.grandviewresearch.com/industry-analysis/ceramic-tiles-market#:~:text=b.-,The%20global%20ceramic%20tiles%20market%20size%20was%20estimated%20at%20USD,USD%20366.4

%20billion%20in%202020.&text=The%20global%20ceramic%20tiles%20market%20is%20expected%20to%20grow%20at,USD%20582.68%20billion%20in%202027.

https://www.alliedmarketresearch.com/us-sanitary-ware-market

https://www.imerys.com/news-stories/Something-to-smile-about-a-100-natural-minerals-based-toothpaste

https://www.imerys.com/news-stories/using-minerals-prevent-contamination-medicines

https://gardenbeast.com/perlite-guide/

https://www.sibelco.com/iota-high-purity-quartz/